套管、油管、井口和井下组件的超声波成像

- 应用领域

- 井下成像

井下成像

我们为检查套管、油管、井口及井下部件设立了新的标准。我们发现、量化并呈现以前从未见过的缺陷。

高分辨率声波井下评估系统

耐用性强

实地验证

DarkVision 的 HADES™ 被公认为整个行业中技术最先进的检查平台。我们的技术被应用于每一个主要的传统和非传统的北美盆地。

- 成像射孔

- 高分辨率空间数据的太字节

- 采集声波图像

HADES™ 平台将 DarkVision 独特的高分辨率声波成像技术与先进的机器人技术相结合,提供无与伦比的井下成像能力。

精确的三维测量,准确的结果。

0.01 英寸分辨率

我们的工具提供更高的分辨率,以便您可以清晰地识别问题并确定故障的根本原因。

多达 512 个独立换能器

我们使用高密度阵列仅能实现的专有成像模式捕获全周扫描。

高保真三维可视化

告别主观解释。我们的系统以高保真、直观的三维可视化提供无与伦比的清晰度。

实地验证和信任

我们屡获殊荣的技术已在所有北美传统和非传统盆地的 75 多家运营商的现场得到验证。

直接测量

我们直接捕获尺寸精确的三维数据,无需主观解释。

对流体无差别

我们的声波成像系统对流体无差别,能够在水、盐水、钻井泥浆和生产液体中进行扫描。再也不会因为浑浊或不清晰的液体而丢失数据。

超过 100 家运营商实地验证和信任

井完整性评估

确保井的安全运行,提高爆破压力的准确性,并通过前所未有的厚度和变形数据确定故障根源。我们提供完整的油管、套管和连接器的周向成像,以消除校准器和摄像机等传统技术的盲点。

射孔侵蚀分析

通过市场上最全面的射孔侵蚀分析产品,最大限度地提高生产率,提高操作效率,并识别堵塞损坏。我们捕捉每个射孔的尺寸精确的3D测量数据,并为您提供基于机器学习的增长分析。哦,而且您不需要更换液体。

复杂组件检查

获取前所未有的亚毫米级数据,帮助您诊断复杂表面和井下组件故障。无论是井口、地下安全阀、衬管悬挂器还是ICD(进出口调节阀),我们都能找到损坏、变形、椭圆形和泄漏路径。

障碍物和限制

实时获取无与伦比的朝下3D图像,以最大限度地减少非计划停机时间。我们通过提供阻碍您井的数字孪生技术来消除歧义,并在井口实时完成。

Case Studies & White Papers

- CASE STUDY

MAY 4, 2022

Fiber Clamp Mapping

- WHITEPAPERS

MARCH 25, 2021

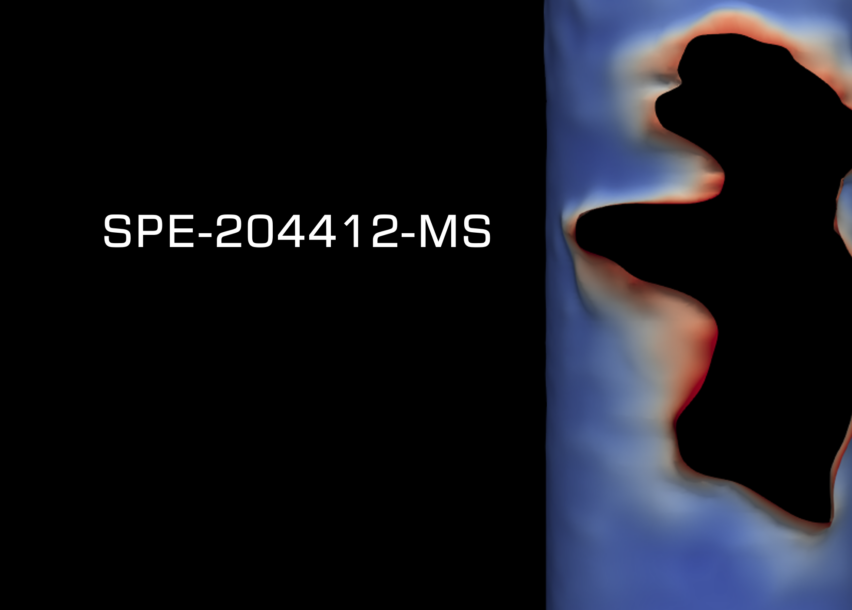

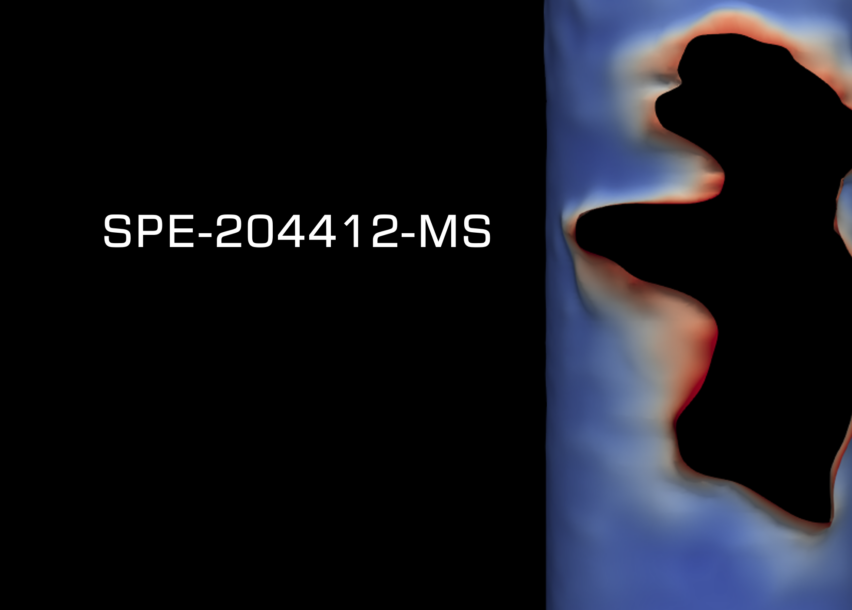

ICoTA 2021: Award-Winning Research on Plug-Induced Casing Damage

- CASE STUDY

JANUARY 21, 2022

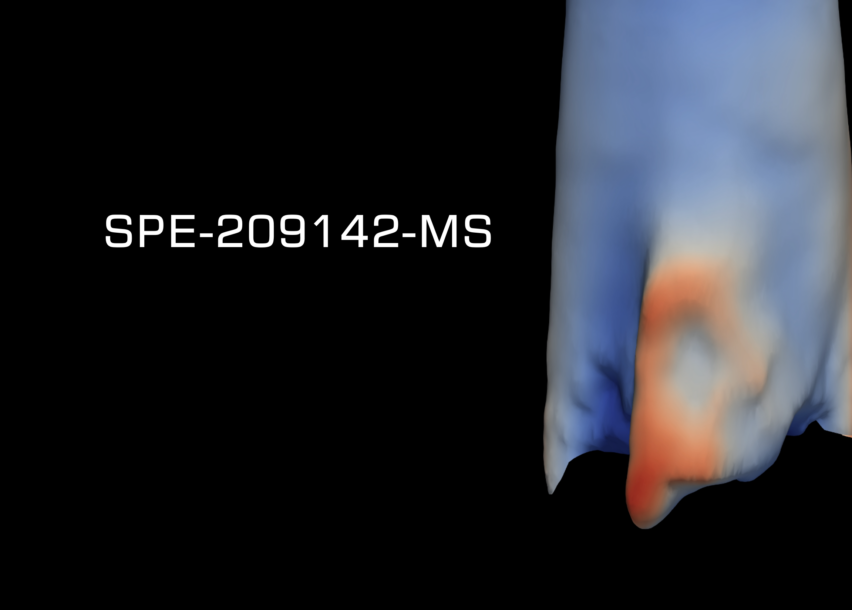

Sheared ESP Casing Obstruction

- WHITEPAPERS

JULY 10, 2021

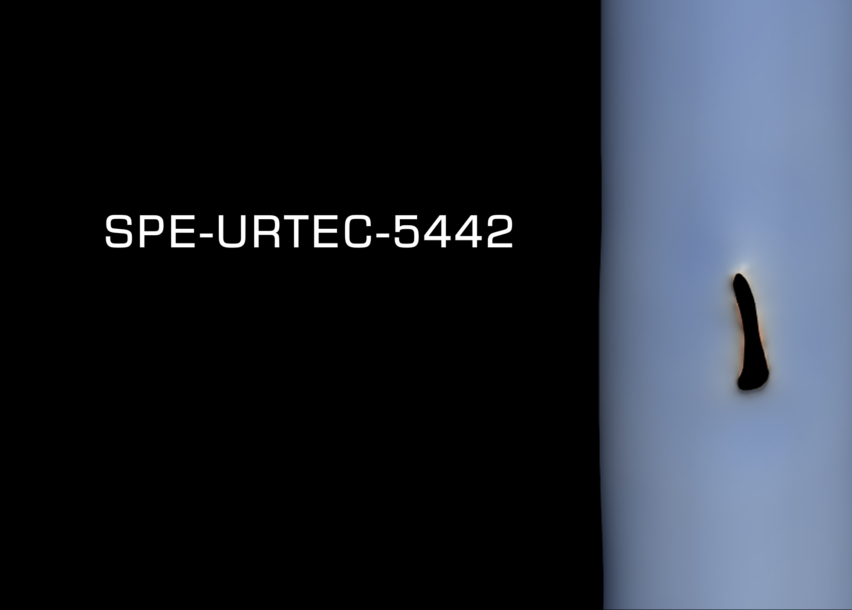

URTeC 2021: Quantifying Complex Perforation Growth

UNLOCK CONTENT

- CASE STUDY

OCTOBER 26, 2021

Post-Frac Wellhead Inspection

- CASE STUDY

AUGUST 26, 2021

Severe Corrosion Casing Inspection

- WHITEPAPERS

FEBRUARY 5, 2022

HFTC 2022: 4-DOF Robotics & High-Res Acoustic Imaging

- WHITEPAPERS

FEBRUARY 10, 2020

HFTC 2020: 30,000 Perforation Measurements and Counting

- CASE STUDY

MAY 4, 2022

Fiber Clamp Mapping

- WHITEPAPERS

MARCH 25, 2021

ICoTA 2021: Award-Winning Research on Plug-Induced Casing Damage

- CASE STUDY

JANUARY 21, 2022

Sheared ESP Casing Obstruction

- WHITEPAPERS

JULY 10, 2021

URTeC 2021: Quantifying Complex Perforation Growth

UNLOCK CONTENT

- CASE STUDY

OCTOBER 26, 2021

Post-Frac Wellhead Inspection

- CASE STUDY

AUGUST 26, 2021

Severe Corrosion Casing Inspection

- WHITEPAPERS

FEBRUARY 5, 2022

HFTC 2022: 4-DOF Robotics & High-Res Acoustic Imaging

- WHITEPAPERS

FEBRUARY 10, 2020

HFTC 2020: 30,000 Perforation Measurements and Counting

- CASE STUDY

MAY 4, 2022

Fiber Clamp Mapping

- WHITEPAPERS

MARCH 25, 2021

ICoTA 2021: Award-Winning Research on Plug-Induced Casing Damage

- CASE STUDY

JANUARY 21, 2022

Sheared ESP Casing Obstruction

- WHITEPAPERS

JULY 10, 2021

URTeC 2021: Quantifying Complex Perforation Growth

UNLOCK CONTENT

- CASE STUDY

OCTOBER 26, 2021

Post-Frac Wellhead Inspection

- CASE STUDY

AUGUST 26, 2021

Severe Corrosion Casing Inspection

- WHITEPAPERS

FEBRUARY 5, 2022

HFTC 2022: 4-DOF Robotics & High-Res Acoustic Imaging

- WHITEPAPERS

FEBRUARY 10, 2020

HFTC 2020: 30,000 Perforation Measurements and Counting